How much does it cost to build a tyre recycling plant? This is a very common question asked by people who are planning to set up a tyre recycling plant. A tyre recycling plant is not only a profitable business but it also helps to conserve the environment. However, before you start with this ambitious projects of building a waste tire recycling machine, it is very important to take into consideration factors that will impact directly on the cost of building a tyre plant. The truth is that there is no definite answer to the amount of money you will use to set a tyre a recycling plant. In this article, we are going to discuss factors that will determine how much you are going to use when building a tyre recycling plant.

1. Size of the plant

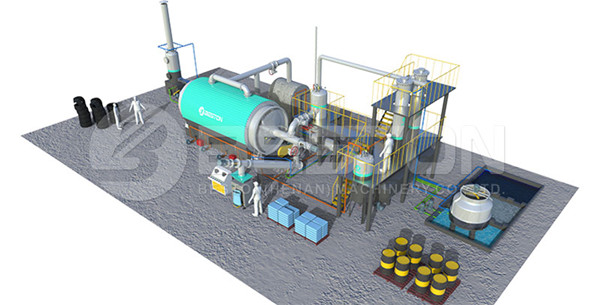

The first very important factor that will determine how much it will cost to build a tyre recycling plant is the size of the plant that you are planning to build. For instance, if you planning to building a tyre recycling plant with large capacity, then you must be prepared to dig deep into your pocket when compared to if you are planning to build a plant with small capacity. A plant with large capacity means that you will have to purchase large machines besides having bigger space, a factor that will impact directly on the waste tyre recycling plant project cost. This means that it will actually cost you more if you are planning to build a plant with large capacity.

2. Quality of machine used

The output of a tire recycling plant for sale will depend on the quality of machine used. There are very many companies that claim sell quality plant recycling machinery. The quality of machines that you choose will impact directly on the cost. This means that if you buy quality tyre recycling machinery, then you will have to dig deeper on your packet when compared to buying a machine that is of low quality. However it is very important to note that cheap always turn out to be expensive. Experts recommend that you buy quality tyre recycling machinery for your tyre recycling plant project.

3. Government policy

Terms and conditions that the government has put in place will also impact directly on how much it will cost you to build a tyre recycling plant. Government polices include thing such as environmental regulations, tax that you are going to pay as well as political and social economic factors. Get free quote of the machine here: bestonpyrolysisplant.com/.

Other factors that will impact directly on how much you are going to spend to set up a tyre recycling plant is the cost of machine maintenance, energy bill, as well as wages for workers. For instance, if you buy quality tyre recycling machine for your plant, then it will actually require less maintenance meaning that you will spend less when compared to buying a machine that will require regular maintenance. The same also applies to the quality of workers you employ.