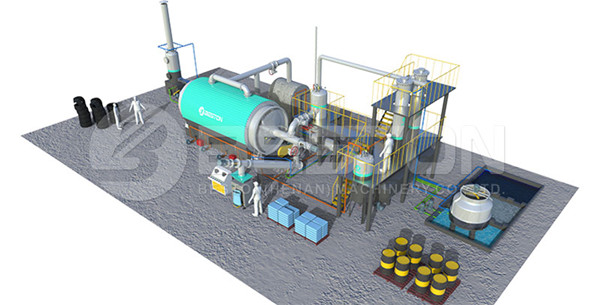

Among the key challenges faced in recycling the major quantity of plastic, utilizing the conventional recycling procedures, is that all of the plastic waste want to be isolated and recycled differently utilizing specific special process. This process is labor intensive, tedious, expensive and further, few of the plastics cannot be reused. Good quality continuous pyrolysis plant uses latest technologies to recycle combined plastics and car parts wastes without the required for isolation. Continuous plastic pyrolysis machine changes plastic to carbon black and oil without polluting the atmosphere. The machine includes traits auto feeder that input the wastes in to the reactor.

Environment and energy:

These wastes are then heated utilizing coal, organic gas, oil or wood. At 250 degree Celsius, it is transmitted to oil gas. The oil gas is condensed to make liquid oil, gathered in the oil tank. The rest of the gases which cannot be cooled with the usual pressure are recycled for further heating in to the reactor. By this way, energy is saved and the surrounding is also well protected. The leading smoke which comes from burning the plastic wastes can be avoided from contaminating the atmosphere by dual desulfurization and dusting cleaning equipment. After the oil is received from the recycling plant, the total process is cooled to make carbon black that can be discharged without any damage. Immediately the temperature fall under hundred degrees Celsius, another plastic wastes recycled is input in to the machine. Find out the most professional pyrolysis machine manufacturers.

Pyrolysis process:

Continuous plastic pyrolysis machine process let raw material feeding as well as carbon black releasing continuously. The pyrolysis process is done by a high automation system and has special equipment that has thermometer, valve, pressure valve, water seal, and oil water separator. Moreover, the procedure has rigid testing units from raw material which check the material at each step till the machine manufacturing. The continuous waste tyre pyrolysis plant recycles plastic wastes that a atmospheric pollutant as well as change the waste to oil that is a promotable product. The complete process begins form feeding the plastic wastes in to the system to releasing the carbon black is wholly controlled by PLC. Continuous plastic pyrolysis plants are not found in the market.

Benefits:

The plastic into oil machine contain high ability and can approve high capacity of continuous plastic wastes, send by a process prior being changed in to crude oil at reasonable price. The truth that the machine can change the dangerous atmospheric contamination, plastics to oil that is one of the valued liquids in the globe. Plastic products are the materials of crude oil and had saturated the earth. Due to the reason of its prosperity and with the establishment of the continuous pyrolysis plant, that can change the famous pollutant, the earth can today advance at a greater pace. This machine has many beneficial features. It is environmentally friendly, energy saving and available at a cheap rate. Due to the reason it offers many advantages, it is necessary to buy a qualified continuous plastic waste pyrolysis machine. More cost information on tyre to oil plant.