Over years, there has been an advancement of technology used in the construction industry. If you are in the building industry, you know about the dry mortar plant. So What Would You Do With Mini Dry Mortar Mixer In Construction Site?

Nowadays, the dry concrete mixes have high demand in the construction industry. Materials for waterproofing, floor making, and plastering mixes comes from the dry concrete mixer. The modern-day dry concrete mixes are not the simple mixture of sand and cement, but it is an advanced technology product. In this case, the mini mortar mixers produce top quality products that increase the working efficiency.

What is Dry mortar?

This is an advanced technology that has gained wide acceptance in most parts around the world. The cost of dry mortar can be high as compared to job site mortar. However, dry mortar can minimize the labor costs while achieving high speeds in construction. The wastage of sand is minimized while making the dry mortar.

Materials used for making dry mortar

The main components used for making dry mortar include:

Sand, Cement, Limestone powder, Hydrated lime

However, you can add other materials to the dry mortar depending on your intended application.

Uses of dry mortar mix

The dry mortar is used for projects that use concrete. This product is also used for a number of applications which include adhesive tiles, filler, and repairing plaster. Click here to know more: http://drymortarproductionline.net/.

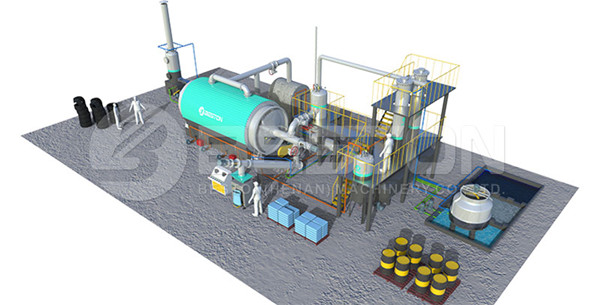

How do mini Dry Mortar Mixer work?

The mini Dry Mortar mixer includes different storage section of sand, cement, and additives. Before mixing these materials, they must pass through a weighing bin to ensure right proportions of the mix. After the right dosage of the components enter the mixer, the mixing process starts. In this case, the mixing time is controlled using an automatic control system.

High quality mixing process: the dry mixer produces high-quality dry mortar mix ideal for constructing high-quality structures. In this case, the materials produced in this mixer have perfect geometrical size. Moreover, the mini Dry mortar mixer makes highly durable materials.

Extensive application range: dry mix mortar mixes can produce a wide variety of masonry mortars, thermal insulation mortars, and dry bonding mortars. In this case, the Mini Dry Mixer has a wide range of applications for onsite constructions. We are the best small dry mortar plant manufacturer, mini mortar mixer is our hot sales product.

Low investment: this is a distinct characteristic of the mini Dry mortar mixer especially when used for thermal insulation and decoration mortar productions. With this machine, you can get quick returns on your investment.

Long service: the mini Dry mortar mixer is made from high-quality parts that include stiff steel. In this case, the machine will have long life hence giving your top-notch service for prolonged periods.

High efficient mixing system: the mini dry Mortar mixer has an automatic mixing system controlled by precise digital controllers. The highly automated can help you achieve appropriate mortar mixes. Moreover, no residue is left behind in the mixer after discharging the mixture. The semi-automatic dry mortar production line has higher productivity.

Conclusion

The mini Dry Mortar mixer offers a lot of benefits on the construction site. This top-notch machine will not only save your time but will also save your money.